Dust Collector Support Cage

“Revolutionizing Filtration for a Cleaner Tomorrow"

ARG Tech India Pvt Ltd Raipur CG, Manufacture Air Filtration Dust Collector Filter cages give the required support to the filtration bags and maintain their shape thereby increasing their longevity. We manufacture with precision, which are available in various configurations to suit specific operational requirements.

Round Cages

Description:

Round cages are the most widely used support structures for filter bags. its cylindrical shape provide uniform support to the filter media, maintaining consistent for airflow and efficient dust collection. These cages are suitable for industries requiring high-efficiency filtration and also minimal airflow resistance.

Key Features:

- Standard design used in most dust collection systems.

- it is good for Uniform air distribution and better dust collection efficiency.

- commonly Available in various diameters and lengths.

- Can be made from mild steel, galvanized steel, or stainless steel.

- Smooth finish to prevent damage to the filter bag.

Applications: Cement plants, steel industries, power plants, food processing, and woodworking.

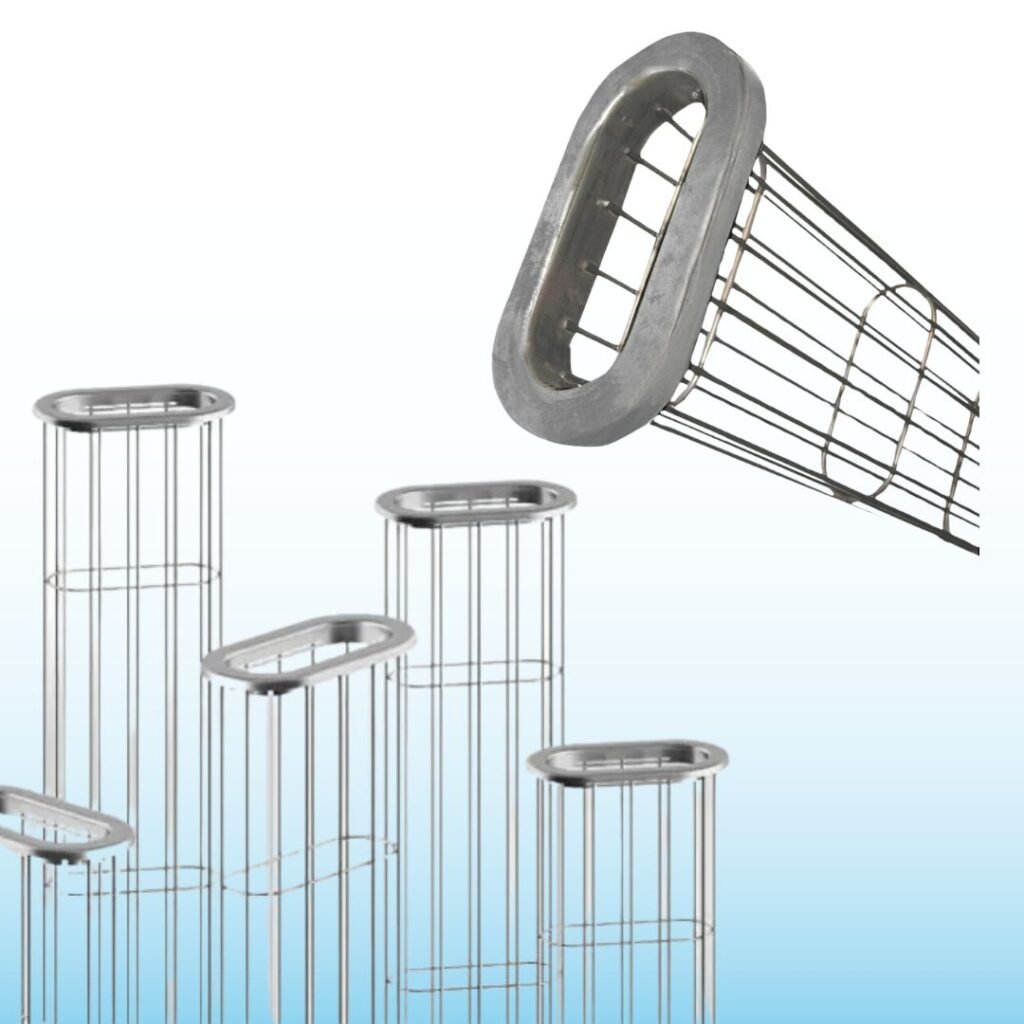

Oval Cages

Description:

Oval cages are make to optimize space which is maintaining high filtration efficiency. its shape allows for better airflow management and low pressure drop. oval cage making ideal for compact dust collection systems. these industries where space is constrained There oval cages are commonly used.

Key Features:

- high filtration efficiency and also Space-saving design.

- Minimizes pressure drop for improved airflow.

- Provides better filter bag stability than round cages.

- Available in a many variety of materials including stainless steel and epoxy-coated steel.

Applications: Chemical processing, pharmaceutical industry, and high-efficiency filtration systems.

Flat Cages

Description:

Flat cages are used in specialized filtration units where space is extremely limited. Their slim design allows for optimal use in compact filtration systems without compromising dust collection performance.

Key Features:

- Compact and efficient design for limited-space applications.

- Ensures high filtration efficiency with strong structural support.

- Can be customized in different widths and lengths.

- For extended durability its Available with anti-corrosion coatings

Applications: Automotive paint booths, small-scale industrial filtration, and cleanroom applications.

Split Cages (Two - Piece )

Description:

Split cages come in multiple pieces that can be assembled on site, designed for easy transport and installation in areas with limited access. They become a great alternative to larger filtration systems where one-piece cages are impractical.

Key Features:

Modular designed for easy transport and installation.

Ideal for industries with space restrictions.

Available in two-piece, three-piece or more configurations.

fast locking mechanism for rapid assembly.

for increased durability used Corrosion-resistant coatings.

Applications: Large-scale industrial dust collectors, power plants and cement plants.

Venturi Cages

A Small, Cone-Shaped Nozzle

Description:

Venturi is a truncated cone-shaped nozzle fitted at the top of the cage to enhance air flow and cleaning efficiency. Cages with venturi help to direct the air pulse more effectively, thereby improving the working of pulse-jet dust collectors.

Key Features:

Improves air flow and increases cleaning efficiency.

Reduces wear of filter bags, thereby increasing lifetime.

Optimizes dust collection performance.

it can be Customizable in various materials and coatings for improved durability

Applications: High-efficiency pulse-jet dust collectors in power plants, cement industries and metal processing units.

Why Choose Our Air Filtration Support Cages?

✅ High-Strength Construction.

✅ Precision Engineering.

✅ Corrosion-Resistant Coatings.

✅ Easy Installation & Maintenance.

✅ Customization Available.

Let's

"Join Us on Our Mission for Cleaner Air"

We invite you to be part of our journey as we build a strong reputation in the industry and contribute to a greener future. Let’s work together to ensure better air quality and optimized industrial performance.

Browse

About Us

ARG Tech India Pvt Ltd is a leading Dust Filtration Filter Bags & Cages manufacturing company in Raipur Chhattisgarh.

+91 91245 68600